skype:

skype:

For some special occasions, the lcd panels may need extra treatment, such as military applications, medical applications,

so it is necessary to know the two popular types of shieding glass, coated shielding glass, and screen glass.

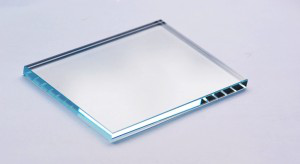

first of all, we talk about the details of coated shielding glass, sometimes it is also called ITO Shielding glass.

When high light transmittance is important and there are only ordinary requirements for shielding effectiveness, coated shielding glass can be used:

Coated shielding glass is a special process to form a dense indium tin oxide ITO conductive film on the surface of tempered glass or ordinary glass,

which has the advantages of high light transmittance, no optical distortion, and strong environmental adaptability.

The surface film resistance has various specifications such as 5 ~ 14Ω. When installing with coated glass, pay attention to the side with the coating on the inside of the terminal to prevent scratches,

and make the coating well contact the conductive coating around the panel to ensure its conductive continuity.

The biggest difference between coated shielding glass and screen shielding glass Difference in light transmittance and shielding effectiveness.

The prominent feature of the film glass is that it has a light transmittance greater than 80%, and the shielding effectiveness is up to about 35dB;

the shielding effectiveness of the screen shielding glass is above 40dB, but the maximum light transmittance that can be achieved

at present is about 70% The screen transmittance of screen-shielding glass with screen effect greater than 80dB is only about 40%.

Low-resistance (≤14Ω) conductive coated shielding glass can be used as a shielding window that requires high light transmittance.

It is available in various thicknesses, mainly including ordinary coated glass and tempered coated glass.

below is the technical index of normal coated shielding glass that are used:

| Shielding effectiveness | Transmittance | Temperature | Thickness | |

| ≤ 5Ω | 35 dB | ≤70% | -40℃~+90℃ | 0.7/1.1/2/3/4/5/6mm |

| 8~10Ω | 32 dB | ≤75% | -40℃~+90℃ | 0.7/1.1/2/3/4/5/6mm |

| 11~14Ω | 30 dB | ≤80% | -40℃~+90℃ | 0.7/1.1/2/3/4/5/6mm |

PREVIOUS:Flicker Analysis for TFT LCD part Ⅱ