skype:

skype:

Industrial ultrasonic flaw detectors are widely used in non-destructive testing (NDT) to detect internal material defects—such as cracks, porosity, and inclusions—ensuring product quality and structural safety. They operate by emitting ultrasonic waves into a test object and analyzing the reflected signals to identify and characterize defects.

Within the flaw detector, the LCD screen serves as the core human-machine interface (HMI), responsible for displaying critical information like waveform images, test results, and parameter settings. The performance of the LCD directly impacts the operator's defect recognition accuracy, work efficiency, and user experience in complex environments. A suitable LCD screen not only provides clear, stable image display but also maintains reliable operation in harsh industrial conditions, thereby enhancing the overall performance of the flaw detector.

1.1 Harsh Environment Adaptation Challenges

Extreme Temperature Fluctuations: Response speed degradation caused by exposure to -20°C low temperatures or 50°C high temperatures during field operations.

Direct Strong Light Conditions: Screen visibility reduction under outdoor inspection scenarios where illumination can exceed 100,000 lux.

Humidity and Corrosion: Accelerated component aging in high-humidity environments (≥85% RH).

Mechanical Vibration and Shock: Connection loosening and pixel failure resulting from mobile detection and on-site operations.

1.2 Professional Technical Performance Challenges

Waveform Display Requirements: High refresh rate (≥120 Hz) needed for ultrasonic A-scan signals to ensure real-time performance.

Color Accuracy: Stringent color reproduction requirements (sRGB ≥95%) for phased array C-scan imaging.

Grayscale Performance: High grayscale levels (≥64 levels) required for B-scan images to distinguish minor signal differences.

Viewing Angle Consistency: Wide viewing angles (178°) needed for multi-person collaborative inspection to ensure consistent viewing from all positions.

1.3 Long-Term Reliability Challenges

Continuous Operation Stress: Backlight attenuation caused by 24/7 uninterrupted operation in industrial settings.

Touch Durability: Touch layer wear resulting from frequent operation (averaging thousands of daily touches).

Component Aging: Slower response times and image persistence (ghosting) due to degradation of liquid crystal material properties.

2.1 Basic Parameter Selection Criteria

Size and Resolution Balance

Recommended Combinations: 10.1-inch (1280×800) / 15.6-inch (1920×1080)

Pixel Pitch: 0.15mm - 0.20mm ensures waveform details are clearly distinguishable.

Brightness and Readability

Indoor Applications: 300 - 600 nits

Semi-Outdoor Applications: 600 - 900 nits

Full Outdoor Applications: >1000 nits, paired with optical bonding technology.

Contrast Ratio and Grayscale

Static Contrast Ratio: ≥ 1000:1

Dynamic Contrast Ratio: ≥ 50000:1

Grayscale Levels: ≥ 64 levels (8-bit color depth)

2.2 Environmental Adaptability Requirements

Operating Temperature Range

Standard Industrial Grade: -20°C to 70°C

Enhanced Industrial Grade: -30°C to 80°C / -40°C to 85°C (heating function optional)

Ingress Protection (IP) Rating

IP65: Dust-tight and protected against water jets. Suitable for standard industrial environments.

IP67: Dust-tight and protected against temporary immersion. Suitable for damp environments.

IP69K: Dust-tight and protected against high-pressure, high-temperature water jets. Suitable for extreme operating conditions.

Vibration Resistance Design

Amplitude Tolerance: 5-19Hz / 1.2mm

Acceleration Tolerance: 19-200Hz / 1.2g

Shock Tolerance: 15g acceleration (11ms duration)

2.3 Technical Specifications

Response Time

Typical: ≤ 15ms (Gray-to-Gray)

High-Speed: ≤ 8ms (suitable for fast waveform refresh)

Color Performance

Color Gamut Coverage: sRGB ≥ 92%

Color Uniformity: ΔE < 3

Color Depth: 6-bit / 8-bit / 10-bit (select based on inspection requirements)

Touch Technology Selection

Resistive: Suitable for gloved operation; high precision but lower durability.

Projected Capacitive (PCAP): Supports multi-touch; good durability but may require special gloves.

Infrared (IR): No surface wear; suitable for high-frequency use environments.

2.4 Interface and Signal Compatibility

Interface Type

LVDS: Industrial standard; strong noise immunity; long transmission distance.

eDP: Supports high resolution; fast transmission rate.

MIPI: Commonly used in mobile devices; fewer pins.

Power Requirements

Voltage Range: 3.3V / 5V / 12V (select based on system design)

Power Consumption Control: Backlight typically accounts for 60-70% of total power; power efficiency optimization is required.

03 Application Scenario Case Studies

3.1 Case Study 1: Eddy Current Flaw Detector in Aerospace Applications

Equipment Type: Phased Array Flaw Detectors

Application Scenario: Inspection of aircraft engine blades and composite materials

Environmental Characteristics:

Significant light level variations in hangars (200-1000 lux)

Requirement to accurately identify minute defects (≥Φ0.5mm)

Need for multi-person collaborative inspection

Selected Solution:

Screen Specification: 10.1-inch IPS wide-viewing-angle screen

Resolution: 1920×1200 (224 PPI)

Brightness: 1000 nits, supports automatic brightness adjustment

Touch Technology: Projected Capacitive, supports 10-point touch

Special Features: Sunlight-readable mode, color accuracy with ΔE < 2

Technical Advantages: High resolution ensures clear details in phased array S-scan images; wide viewing angle facilitates simultaneous viewing by multiple personnel; high color accuracy guarantees defect identification reliability.

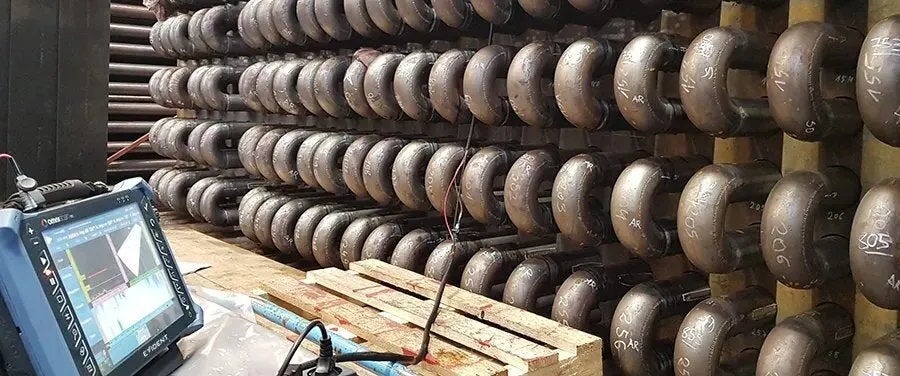

3.2 Case Study 2: Eddy Current Array Flaw Detector in Petrochemical Applications

Equipment Type: Eddy Current Array Flaw Detectors

Application Scenario: Corrosion inspection of pipelines and storage tanks in refining equipment

Environmental Characteristics:

High ambient light conditions (direct illumination >100,000 lux)

Presence of vibration and shock

Corrosive gas environment

Selected Solution:

Screen Specification: 12.1-inch high-temperature LCD

Resolution: 1280×800

Brightness: 1500 nits, combined with anti-glare surface treatment

Protection Rating: IP67, fully sealed design

Technical Advantages: Ultra-high brightness ensures visibility in direct sunlight; IP67 rating prevents ingress of corrosive gases and liquids.

3.3 Case Study 3: Multi-function Ultrasonic Flaw Detector in Railway Inspection Applications

Equipment Type: Ultrasonic Flaw Detectors

Application Scenario: Rail weld and wheel inspection

Environmental Characteristics:

All-weather outdoor operation (-20°C to 50°C)

Frequent movement and vibration

Need for fast waveform refresh and operational response

Selected Solution:

Screen Specification: 8.4-inch high-brightness LCD

Resolution: 800×600

Brightness: 800 nits

Response Time: ≤10ms

Touch Technology: 5-wire resistive, supports operation with gloves and stylus

Technical Advantages: Fast response time ensures real-time display of A-scan waveforms; resistive touch supports gloved operation; moderate size facilitates portability and handheld use.

4.1 Priority Ranking

The following is a checklist of core parameters for selecting LCD screens for industrial ultrasonic flaw detectors:

Environmental Adaptability: Operating temperature range, IP rating, vibration resistance

Display Performance: Brightness, contrast ratio, response time

Reliability: MTBF, backlight lifetime, touch durability

Cost & Lead Time: Price, supply cycle, technical support

4.2 Decision-Making Process

Requirements Analysis → Technical Parameter Confirmation → Initial Supplier Screening → Sample Testing → Environmental Adaptability Verification → Small Batch Trial → Bulk Purchase Decision

Brand Selection

It is advisable to prioritize well-known brands such as AUO, BOE, Kyocera, LG, and Innolux. These brands typically offer strong advantages in product quality, after-sales service, and technical support.

Supply Chain Stability

Select suppliers with a stable supply chain to ensure continuous product availability and reliable after-sales service.

Technical Parameters & Performance

When selecting an LCD screen, comprehensively consider technical parameters such as resolution, brightness, contrast ratio, response time, and interface type based on specific application requirements to ensure the product performance meets actual needs.

After-Sales Service

Choose suppliers that provide comprehensive after-sales service to ensure prompt resolution of any issues encountered during use.

06 Frequently Asked Questions

6.1 Technical Questions

Q1: How to balance screen brightness and power consumption?

A: It is recommended to select screens with a dynamic backlight control function. This increases brightness for visibility in bright environments and automatically reduces brightness to save power in darker conditions. Also, choose high-efficiency LED backlights to improve brightness while controlling power consumption.

Q2: What is the impact of response time on ultrasonic testing?

A: Response time directly affects the real-time performance and accuracy of waveform display. A slow response time (>20ms) can cause waveform display lag and motion blur in dynamic images. Screens with a response time of ≤15ms are recommended; for high-speed inspection applications, products with ≤8ms should be selected.

6.2 Application Questions

Q3: How to resolve slow screen response in low-temperature environments?

A: Options include selecting wide-temperature screens with built-in heating films, which automatically heat up to the operating temperature upon startup in cold conditions. Alternatively, choose LCDs using low-temperature materials (e.g., LTPS or Oxide TFT), which maintain good response characteristics at low temperatures.

Q4: How to determine if a screen's outdoor readability meets requirements?

A: Assess this by calculating the screen's Contrast Ratio (CR): CR = (L_s + L_a) / (L_b + L_a), where L_s is screen luminance, L_b is screen black-state luminance, and L_a is ambient illuminance. A CR ≥ 3 is considered acceptable for readability, while ≥ 5 is considered good.

6.3 Procurement & Maintenance Questions

Q5: Where do the cost differences between industrial and commercial screens primarily lie?

A: The additional costs for industrial screens mainly come from: wide-temperature components (30-40%), ruggedized construction (20-25%), special optical treatments (15-20%), extended lifespan design (10-15%), and low-volume production (10-15%). However, these investments significantly enhance equipment reliability and service life.

Q6: How is the screen's Mean Time Between Failures (MTBF) validated?

A: MTBF can be estimated through accelerated life testing. A common standard involves continuous operation at 60°C and maximum brightness for 1000 hours, evaluating brightness decay and pixel defects. Industrial-grade screens should have an MTBF ≥ 50,000 hours and a backlight lifetime ≥ 30,000 hours (until brightness decays to 50%).

If you are interested in our industrial LCD screens or want to learn more about how to choose the most suitable brightness parameters based on your specific applications, we welcome you to contact us at any time. Our expert team will provide you with professional consultation and support to help you find the most suitable industrial display solution for your needs.

Please contact us through the following methods to start your journey to a customized solution:

Visit our official website: [www.lhlcdpanel.com]

Send an email to: [celia@leehon.com]

Call us at: [0086-15906639973]

We look forward to working with you to bring you greater value.